Manufacturing Capabilities

Globe Tech Fortune – Manufacturing Capabilities that Drive Global Industries

Globe Tech Fortune Industries Pvt Ltd stands at the forefront of precision manufacturing, offering a complete range of services including CNC Turning & Milling, Cold Forging, Heat Treatment, Plastic Injection Molding, and Laser Cutting (future expansion). With advanced equipment and highly skilled teams, we deliver complex, high-accuracy components for automotive, aerospace, defense, and industrial applications.

Our fully integrated “Under One Roof” facility ensures total process control — from raw material to finished product — enabling faster lead times, superior dimensional accuracy, and consistent quality. Backed by IATF 16949:2016 certification, we are a trusted partner for OEMs and Tier-1 suppliers across the globe.

Our Core Manufacturing Capabilities

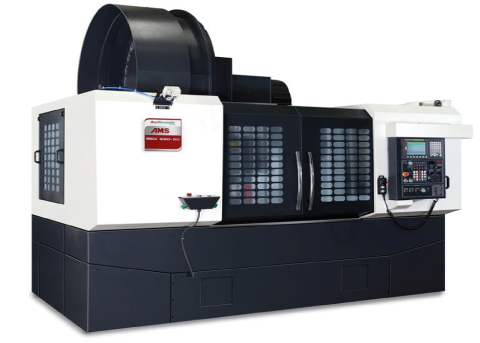

- CNC Turning (⌀20mm to 1000mm) and Milling (25mm to 3000mm) for complex, precision components

- Cold Forging – High-strength, net-shape parts with exceptional dimensional accuracy

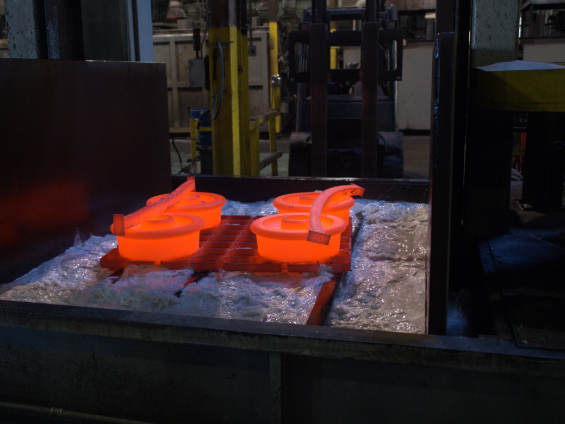

- SCADA-controlled Heat Treatment – Carburizing, annealing, hardening, and stress relieving

- Plastic Injection Molding – Custom parts from 5gm to 90gm using engineering plastics

- Laser Cutting (future expansion) – Accurate cutting of MS, SS, brass, and copper up to 25mm thick.

Polymer Quenching

- Custom Quench Systems – Tailored polymer cooling solutions.

- Maintenance – Keep systems running at peak performance.

- Process Optimization – Improve cooling cycles and results.

- Training – Safe and efficient operation guidance.

Micro hardness tester

Matsuzawa Japan

Microscope

Metji Japan

Sample cutting machine

Chennai Metco

Specimen mounting machine

Metji

Polishing machine

Chennai Metco

Globe-tech Fortune has the following processing sections

CNC Machining Services

Cold Forging

Heat Treatment

Jigs and Fixtures

CNC Milling

Carbo Nitriding Heat Treatment

Precision Tooling

Heat-Treatement-Facility SCADA controlled facility

- Carburizing & Hardening (case depth 0.2 to 4.0mm)

- Carburizing & Annealing (case depth 0.2 to 4.0mm)

- Through Hardening

- Carbo nitriding

- Normalizing

- Annealing

- Stress relieving

- Stabilizing

- SCADA controlled Facility